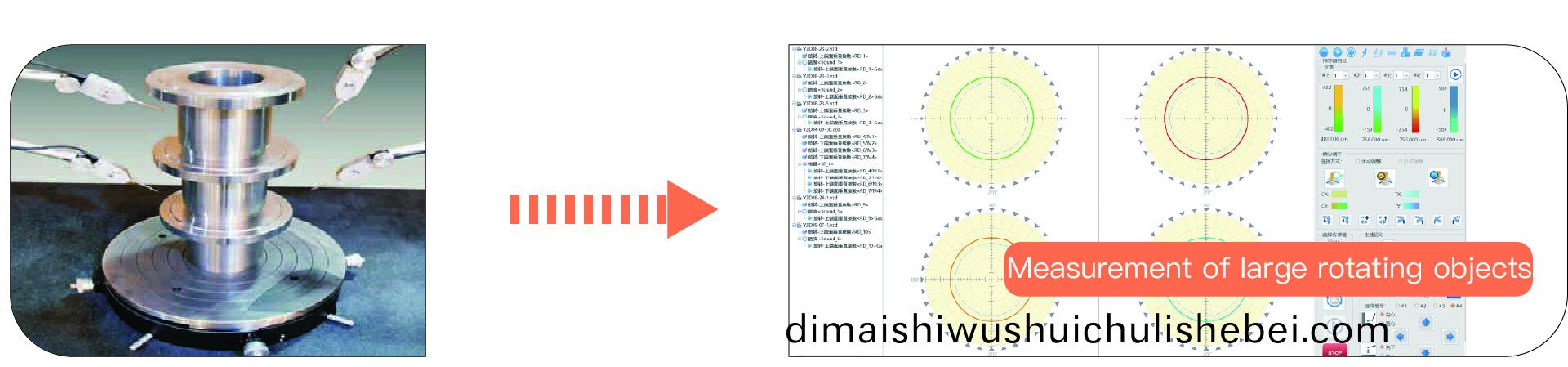

Main Parameter:Using the high-precision air float rotary table as the measurement reference table, the measured rotor is driven to rotate evenly at a fixed speed, while the errors at different positions of the rotor are measured simultaneously and displayed in real time

Integrated turbine rotor measurement and assembly platforms

Customized large rotary precision assembly turnable

MEASURING FUNCTIONS

● Test geometric tolerances, such as jumping and concentricity of various cases, drum cylinders, discs, shafts and other parts;

● Test the parallelism, coaxial axis, verticality, etc. of the part assembly benchmark in the process of assembling, and give the comprehensive characteristic value of the revolution component;

● With an optimization algorithm, guide the assembly process of the revolution component to achieve the measurement needs of the optimization assembly of the revolution composition;

MEASURING PRINCIPLES

Using the high-precision air float rotary table as the measurement reference table, the measured rotor is driven to rotate evenly at a fixed speed, while the errors at different positions of the rotor are measured simultaneously and displayed in real time by high-precision sensors, and the measurement results are finally analyzed and obtained automatically by computer software.

Customizable Items

●? Column ●? Guide Rail ●? Main Axis ●? Software ●? Worktable

TECHNICAL PARAMETERS

Normal Technical Parameters

Item | Parameter |

?Rotary table diameter | 500~2000mm |

Parts turning diameter | 600~2400mm |

Rotary table load capacity | 100~2000Kg |

Max measuring height | 500~2500mm |

Axis radial rotation error | ≤0.2μm |

Worktable runout | ≤10μm(φ 800) |

Worktable flatness | ≤8μm(φ 800) |

Centering and leveling table | Auto/Manual(optional) |

?Customized or OEM is available upon specific request.

High speed roundness measuring instrument Large roundness measuring instrument High robustness/ideal price-performance roundness measuring instrument Pipes roundness measuring instrument Contact roundness measuring instrument Compact type roundness measuring instrument Fully automated roundness measuring instrument Easy operation roundness measuring instrument High rotation accuracy roundness measuring instrument Table-rotating type roundness measuring instrument Standard model roundness measuring instrument Reference roundness measuring instrument Workshop roundness measuring instrument Laboratory roundness measuring instrument Bearing roundness measuring instrument High accuracy roundness measuring instrument Top class roundness measuring instrument Highly accurate robust roundness measuring instrument Ultra-precision roundness measuring instrument High precision roundness/cylindricity measuring system Highest precision reference class roundness measuring instrument High quality measuring tools Roundtest?roundness?measuring instrument Industry-standard?roundness?measuring instrument Superior accuracy and repeatability?roundness?measuring instrument Leveling and cylindricity/roundness error assessment?roundness?measuring instrument?Feature inspection circularity and roundness?measuring instrument Surface texture and?roundness?measuring instrument?PC-compliant roundness and cylindrical-form measuring instrument Compact table-top?roundness?measuring instrument Compact desktop?roundness?measuring instrument

?- Download the attachment to view more customized parameters -

?

| Document Name | File Type | Upload Date | Download |

|---|

Address:Tianhui Science Park, Industrial Second Road, Aerospace Base, Chang'an District, Xi'an City

?-?

?-? ?+86 13087559846

?+86 13087559846

Email:philipwang302@http://www.hhwjjxshh.cn

CopyRight ? 2023 Xi'an Wilson Precision Instruments Co., Ltd. All Rights Reserved.